-horizontal mill with twin 500mm pallets and separate loading station

-High speeds with rapids up to 2400 ipm

-Loaded with 60 tools, renishaw probing and 15k spindle

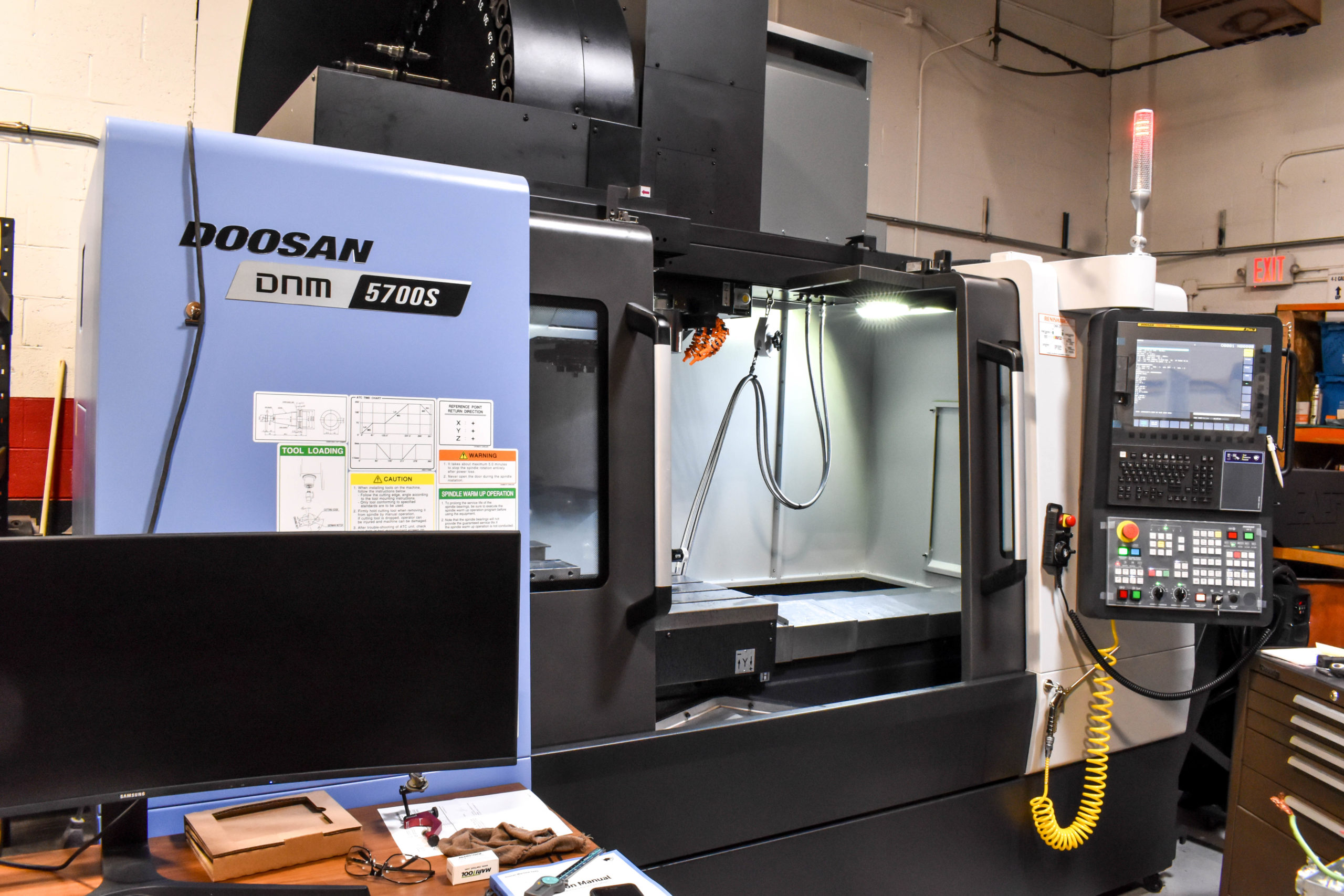

-vertical mill with 40 tools, Renishaw probing and 15k spindle

– High speed machining with rapids near 1500 ipm

– 42” X 21” X 20” work area

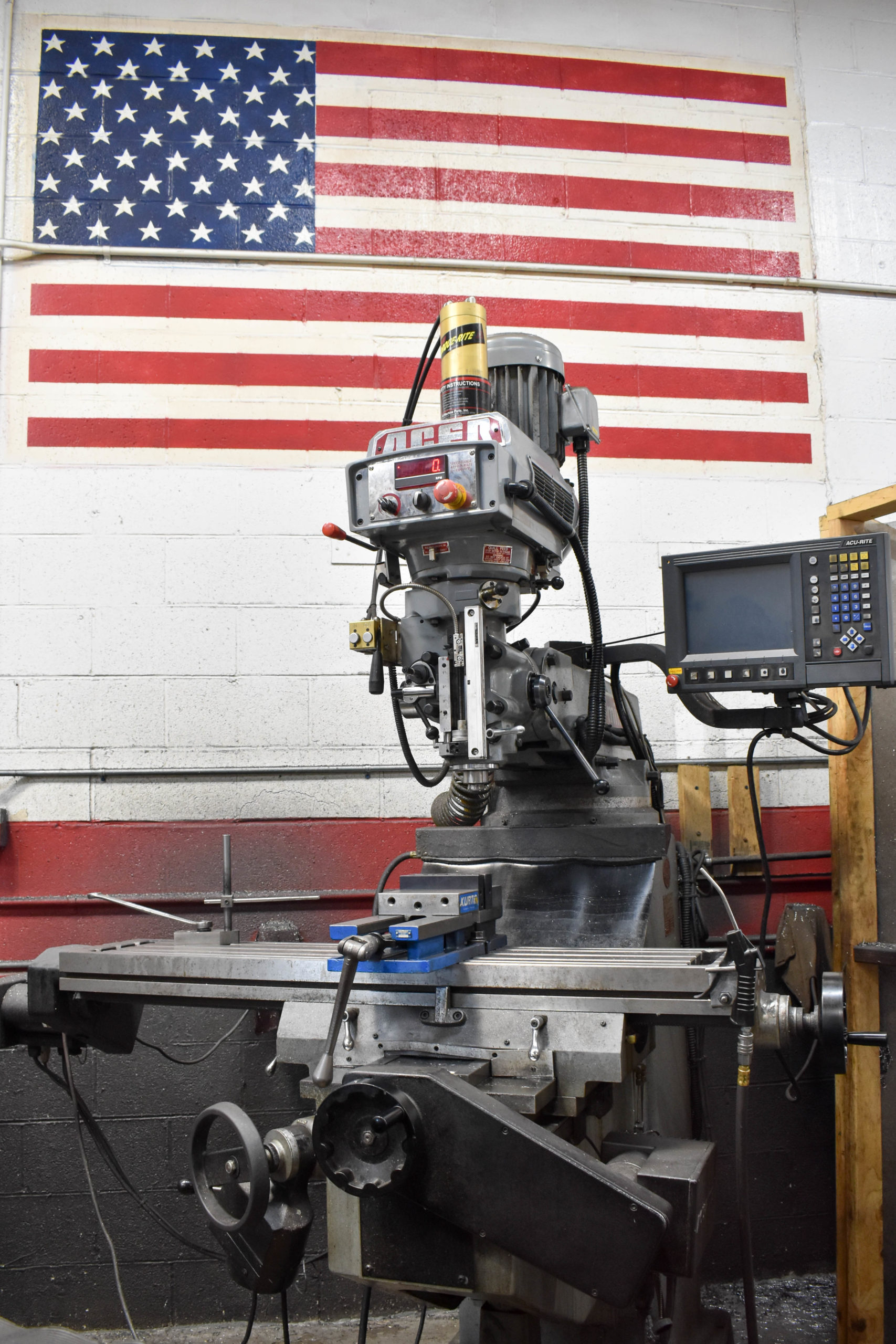

-table size 40 x 20 x 26(height)

-loaded with VPS software, Reinshaw probing system, Flood coolant, rigid tapping, and 31 tool holder, and wired for the 4-axis.

-CNC programmable in MasterCam

-Dual Spindle and Y axis controls

-4′ bar feeder

-Live Tooling

-Parts conveyor

-CNC controlled Lathe

-3″ thru hole, 10″ 3-jaw chuck and 10″ 4-jaw chuck

-14″ max diameter at 40″ max length

-144″ max length at 3″ diameter

-4′ bar feeder with a 2.6″ diameter bar capacity

– Milling and live tooling capabilities

-Lights out manufacturing

-live tooling

-6″ collet and 6″ chuck

-4′ bar feeder that can handle a 1/2-2″ bar size.

Our manual mill department has two machines.

In our saw department we have a roll-in saw to cut material. We also have a chop saw as well to get the job done.

We have the ability to make brackets and do the necessary machine work in one place.

Our Deburring Tumbler helps us get more done in less time. With this machine we get perfectly deburred, finished and clean parts.